HOME

News

International Conference Hall -News

《LA Times》:Digital Transformation in Manufacturing —— Techmation

International Conference Hall -News

2025-10-17

《LA Times》:Digital Transformation in Manufacturing —— Techmation

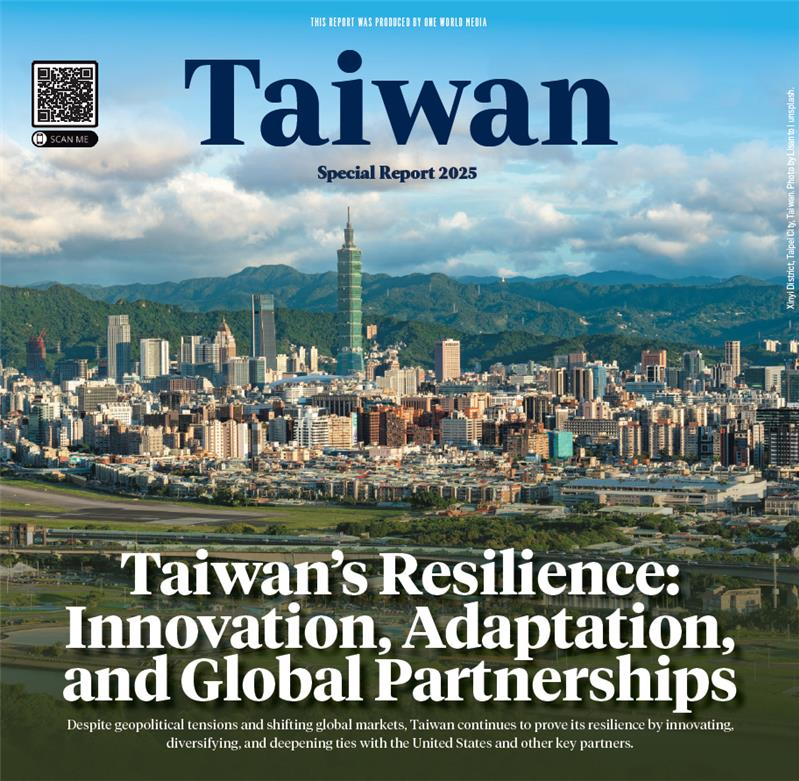

Taiwan has long been at the center of global attention, both for its strategic location and for its outsized role in the world economy. Today, the island faces headwinds ranging from slowing global growth to intensifying US-China competition. Yet Taiwan’s story is not one of fragility, it is one of adaptability.

While trade disruptions and inflation have reshaped supply chains, Taiwan has responded by doubling down on high-value sectors. Electronics, healthcare, and precision machinery remain pillars of growth, while green energy and biotech are emerging as new engines. This adaptability is not accidental; it is the product of decades of investment in education, technology, and strong partnerships.

Digital Transformation in Manufacturing —— Techmation

Global competition is no longer about who can produce more, but who can produce smarter. Taiwanese manufacturers are embracing Industry 4.0 principles – integrating sensors, AI and cloud systems to create intelligent, efficient production lines.

Techmation, a 40-year-old automation pioneer, illustrates this shift. The company has grown from producing injection molding controllers to developing entire automation ecosystems and renewable energy solutions. “Because we own 80 to 90% of our technology, from chips to systems, we are less vulnerable to external shocks,” noted CTO Jerry Hsiung. “That independence allows us to innovate quickly and support both U.S. and Chinese clients.”

Automation leaders are also de-risking their tech stacks to stay agile across markets. Hsiung says the company’s strategy is to control critical IP and push intelligence to the edge. “That depth of in-house capability means we can localize fast without redesigning the core,” he explained. “We’re expanding from plastics into metal forming and general automation, pairing edge controllers with cloud analytics so factories can predict failures, reduce scrap, and redeploy scarce labor to higher-value work.” The philosophy ties back to a simple mission: “Bring the best technology to traditional manufacturing and make it smarter, step by step.”

《LA Times》Taiwan’s Resilience: Innovation, Adaptation and Global Partnerships

閱讀全文 : https://www.latimes.com/specialsupplements/one-world-media/story/taiwans-resilience

Other

2025-05-09